If you thought that nitinol material would make an excellent material to construct heat engines you are not alone. Over the years a number of experimenters and companies have created nitinol heat engines. A patent search on the Internet using the key words nitinol and engine turned up several heat engine designs. Most of the patented designs are mechanically complex and don't lend themselves easily for quick experimentation. However, there is a simple heat engine design that found its way into a few toys. Let's take a quick look at this design.

Thermobile

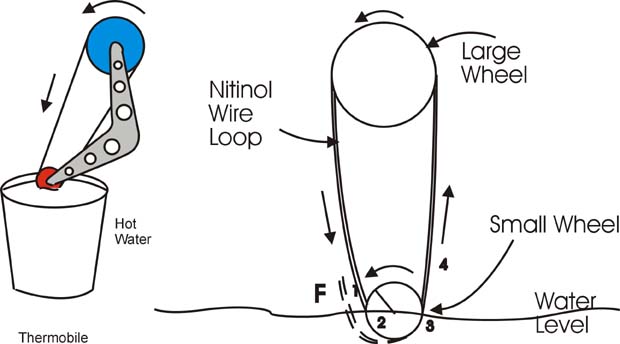

The Thermobile (see figure 8), uses a loop of nitinol wire to generate power. The nitinol loop is place on two free rotating wheels, This device uses only hot water (hot side) and cool ambient air (cool side). The smaller brass wheel of the Thermobile is immersed in a hot liquid.

In the Thermobile the nitinol loop wire has been trained to remember a straight shape. When the loop travels into the hot water it is brought above its transition temperature and attempts to straighten out. Look at figure 9, at position 1 the nitinol wire is relatively straight and cool. As the wire moves from position 1 to 2, it is bent around the small brass wheel and enters the hot water. As the wire moves from position 2 to 3, the hot water brings the nitinol wire above its transition temperature and it tries to straighten out. When attempting to straighten out the nitinol wire takes a form depicted by the dotted lines. In doing so, the wire generates a tugging force, F, along the loop. As the wire segment moves from position 3 to 4 it straightens out. As the wire travels from position 4 to position 1, through the air and around the large wheel it has sufficient time to cool below its transition temperature and is ready for another cycle.

In short, the temperature differential causes one side of the loop to stiffen (hot water side) while on the air side of the loop the nitinol cools and relaxes. A mechanical force is produced that causes the wheel pulleys to rotate.

In some cases it is necessary to jump start the engine by rotating the larger wheel. Interestingly, the Thermobile hasn't a set rotational direction. Whichever way it is started it will continue to rotate. The Thermobile can also be solar powered. A magnifying lens focusing sunlight on the brass wheel also supplies sufficient heat to power the engine.

Larger Thermobile engines have been built and tested using nitinol loops. One engine built by Innovative Technologies International (ITI) in 1982, contained 30 nitinol wire loops. The nitinol wire used in the loops was 22 mils in diameter. The engine was tested using a hot water bath set at 55 C and an air temperature of 25 C. The engine reached a speed of 270 RPM and continued to operate for 1.5 years without failure. The nitinol wire had undergone 2.1x108 cycles without any breakage or observable degradation in performance.

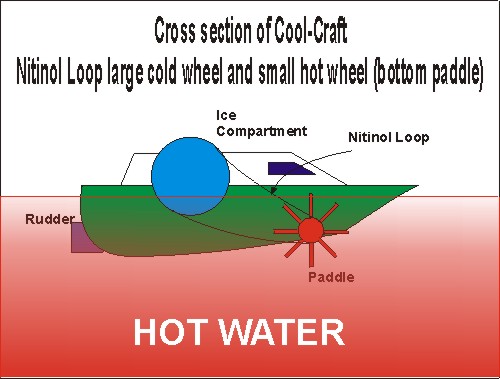

The Cool-Craft boat (see figure 10) also uses a loop of nitinol wire to power a small plastic boat. The nitinol loop is place on two free rotating wheels, see approximate cross section of Cool-Craft boat in figure 11.

The smaller bottom wheel has paddles that move the boat when it rotates. The boat is made with a small ice compartment on top. The top ice compartment chills one side of the nitinol loop. The other side of the nitinol loop travels through warm water where the toy boat is placed. The heat differential between the warm water and ice is enough to activate the nitinol wire loop and power the craft.

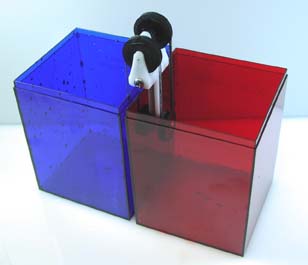

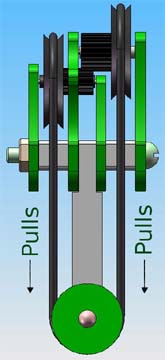

Heat Engine - Nitinol Metal Engine driven by hot and cold water.

The Heat Engineis a very special kind of heat engine that demonstrates

the conversion of heat energy into mechanical energy. Based upon the

work of Dr. Alfred Johnson who was granted a patent on this type of heat engine in 1977 patent # 4,055,955.

It uses the unique property of Nitinol alloy to generate mechanical

motion from heat. Nitinol has trained into a shape at high temperature

(about 600° C) and allowed to cool to room temperature, where it can

be easily deformed and welded into a loop.

When heated above a transition temperature (in this application about

50° C to 70° C) the Nitinol object abruptly returns to its high-temperature

shape with a substantial force that is able to drive the pulleys and

thus create motion.

See

the Heat Engine in action!

More Information