Ohmic Electrical Heating

Direct Electrical Heating Nitinol wire can be activated using a low voltage DC (6-12volts) power supply. A simple circuit can be constructed using a battery, switch and a small length of nitinol wire, see figure 7. When activating a Nitinol wire wire using DC current it is important not to overheat the wire by keeping the current on too long. Overheating the Nitinol wire will degrade its properties. DC current doesn't heat the wire evenly. An electrical circuit that uses Pulse Width Modulation (PWM), shown on the next page, heats the wire more evenly and is better for activating Nitinol wire.

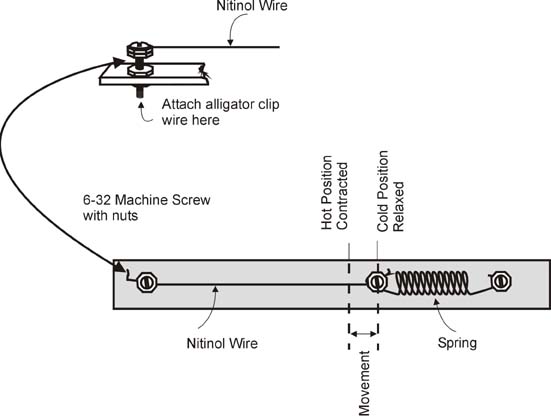

Simple Nitinol Demonstration Figure 8 is a simple mechanical demonstration to display the properties of the nitinol wire alloy. It is basically an electric muscle that flexes. The materials you need are three machine screws (6-32 x 2" length) with nine nuts, a piece of wood or plastic approximately 12" long, a small expansion spring (approx. 2-3" length) and of course a length of nitinol wire. The machine screws, nuts and expansion spring may be purchased at a local hardware store. To make the device, drill two holes in the wood on opposite ends to accommodate the machine screws as shown.

The screw and nuts between the two end screws is not secured to the wood, but is free standing. The nitinol wire is connected to the left screw, see detail in figure 8. The spring is looped around the right end screw. The free standing machine screw and nuts connects the nitinol wire and spring together. Keep in mind the 6-mil nitinol wire has a pull of about 11 oz., so don't stretch the spring so far that the tension is so great the nitinol wire isn't able to contract. At the same time it should be tight enough for it to take the slack of the nitinol wire when it is relaxed.

To make the connections from the DC power supply to the demonstration, use small alligator clip jumper wires connect to the back of the two end screws. The machine screws as well as the spring are electrically conductive, allowing current to flow to the nitinol wire. When you switch on the current to the nitinol wire demonstration unit, the wire heats up quickly, contracts and pulls the freestanding machine screw closer to the right side. If you mark the starting position of the freestanding machine screw, you can accurately measure the contraction of the wire. When power is removed the wire cools, allowing the spring to elongate the nitinol wire and return to its initial position. Since we are using a DC power supply, only connect the power momentarily. It's too easy to over heat the wire and degrade the nitinol properties. On the next page we will build a better electrical circuit to acivate the nitinol wire.