Thermoelectric SunFlower

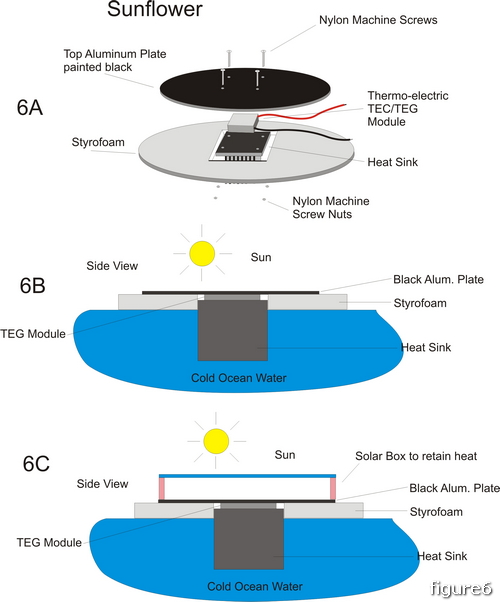

The Sunflower is a passive solar device I designed that uses a Thermo-Electric Generator (TEG). It uses the heat from the sun, to heat the hot side of the TEG and cool ocean water to cool the opposite side see figure 6A.

An aluminum plate is attached to the hot side of the TEG module. The topside of the aluminum plate is painted with a high temperature black paint to improve heat absorption from the sun. Next Styrofoam is attached to bottom side of this plate. I used a spray adhesive on the aluminum plate to secure the Styrofoam. The Styrofoam performs two functions; one as a flotation device to keep aluminum plate and TEG module floating in water, and the second as insulation to keep the water from touching and cooling down the aluminum plate.

The Styrofoam may degrade from the heat of the aluminum plate baking in the sun, but for the prototype, I’m checking function, not longevity or service.

On the opposite side of the TEG module a large deep heat sink is attached. This heat sink is partially submerged in the cold ocean water. This keeps the heat sink cool, which in turn keeps the cool side of the TEG module cold.

Float the sunflower in ocean water and allow time for the top aluminum plate to get hot in the sunlight. Within a few minutes the TEG will begin to generate electric power.

To improve efficiency of the SunFlower, see figure 6C, you can increase heat capture by covering the black aluminum plate with glass, with a 2 inch dead air space, like in a flattened solar oven or solar water heater. This would reduce heat loss from the black plate to the air and wind making the Sunflower far more efficient.

Figure 7 is a photograph of the prototype sunflower under construction. This figure shows the heat sink and the TEG attached to the aluminum bottom side of the Aluminum plate.

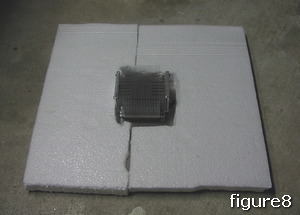

Figure 8 shows the Styrofoam glued to the bottom surface.

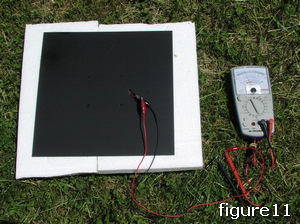

Figure 9 shows the top side of the proto-type with the two electric power wires from the TEG module.

My prototype uses rectangle piece of aluminum, as this was easier to purchase than round shaped aluminum.

I am waiting for summer to test my prototype. I’ll post the results on my company’s website. www.imagesco.com.

Summer Tests results:

May 2010 wasn’t a particular sunny or hot month in NYC. I did have a few 80 degree plus days to bring the sunflower out for some preliminary real world testing. In place of an ocean I had to use a cooking pan filled with ice water, see figure 10. You may question the use of ice in the testing water. Without the ice, the water volume in the pan is so small that I was worried it would have reached ambient outside temperature (80+ F) before the tests could be complete.

I placed the sunflower’s heat sink into the pan of water and left it in the sun for fifteen minutes, see figure

The voltage output at 15 minutes was approximately 0.8 volts, see figure 12. At the half hour mark I checked the current output. It was an impressive 160mA, far more current than I had expected.

Going Further:

The sunflower has not been optimized. To bring this project further, I would do heat studies relating to the thickness of the aluminum material, The current sheet size may be large enough to handle two or three and possible four TEG modules at a time. A little thought can bring this project further along and make it even more impressive.

Solar Thermoelectric Power Generator